A customer approached A Squared during the design phase of a new vessel as they had a requirement to gain a clear understanding of the vessels structural response under design wave loading scenarios.

The customer also required a consultant with practical shipbuilding experience for block-built vessels of steel construction as this input would be important for the identification of build methodology and selection of a preferred shortlist of potential build yards.

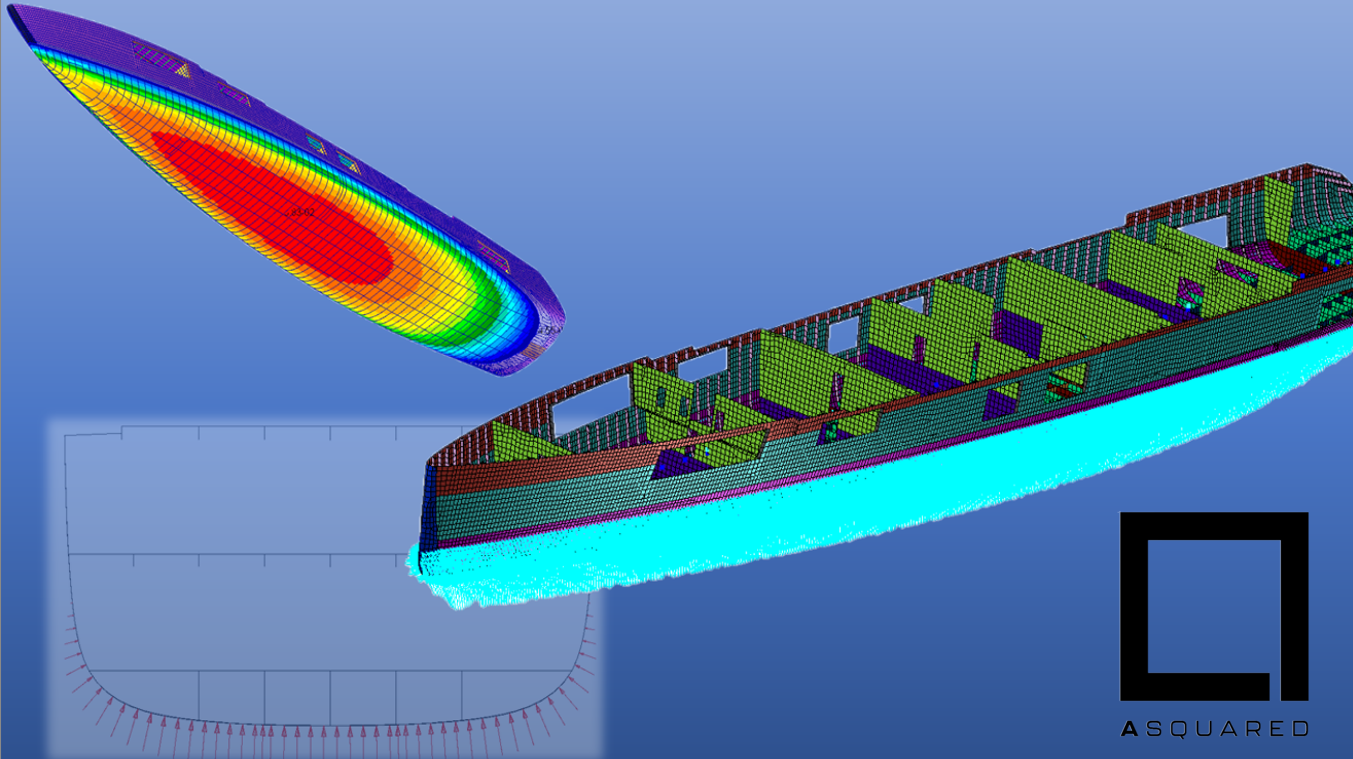

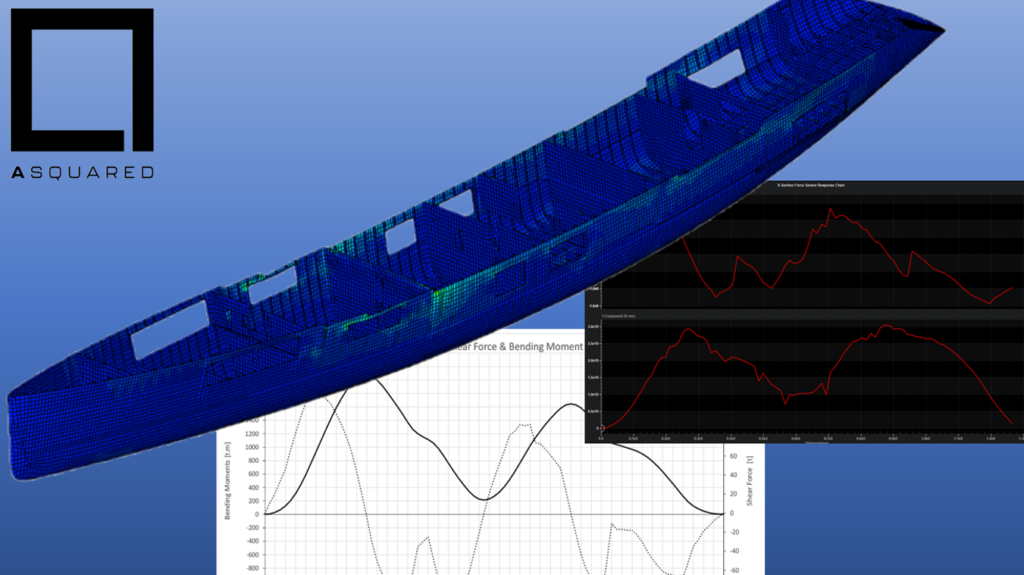

Engineers have been developing scantling arrangements long before state of the art FEA software was readily available. The starting point in our process is to perform a series of simplified manual calculations in accordance with class rules to determine the approximate structural response to simple wave loading for hog and sag. Manual calculations are an essential first step in establishing a baseline scantling arrangement prior to the commencement of any complex numerical analysis. These results also serve as an invaluable benchmark for sense checking initial FEA results.

Utilising MSC Apex to develop a wholeship FEA model of the vessel offers many advantages but the time saving offered in the pre-processing phase is a notable feature that separates APEX from the competition and why it is our tool of choice. Wholeship FEA requires great care to ensure that representative boundary conditions are applied that replicate the behaviour of a vessel floating in a body of water. The model is then balanced, representative wave loads applied and results extracted that can be sense checked and used to validate the suitability of the baseline scantling arrangement……

Analysis is critical phase in the ship design process but is only one component part of of a complex puzzle that is developing a ship design through from concept to a state of readiness for production. The assembled A Squared project team brought together several decades of experience in steel shipbuilding advising the customer on structural details, suitability of materials and all matters pertaining to buildability.

A team was a assembled that plugged the holes in the experience and knowledge of the clients own technical team. Through a collaborative process A Squared were able to ask pertinent questions at the right time in the process to help guide the design process in the required direction cognisant of both technical engineering and practical steel shipbuilding considerations.

A Squared delivers engineering to be proud of in a range of areas across the offshore, oil and gas, marine renewable and commercial marine sectors. We specialise in structural design and analysis and naval architecture.

A Squared Engineering Ltd is registered in Scotland with Company Number SC610793